Rocket motor test stand, designed and built at VCU

The purpose of this test stand is to provide VCU and neighboring universities a universal platform to test and characterize student built rocket engines. This is the first of it’s kind at VCU, which further pushes the propulsion capabilities at our university.

My roles

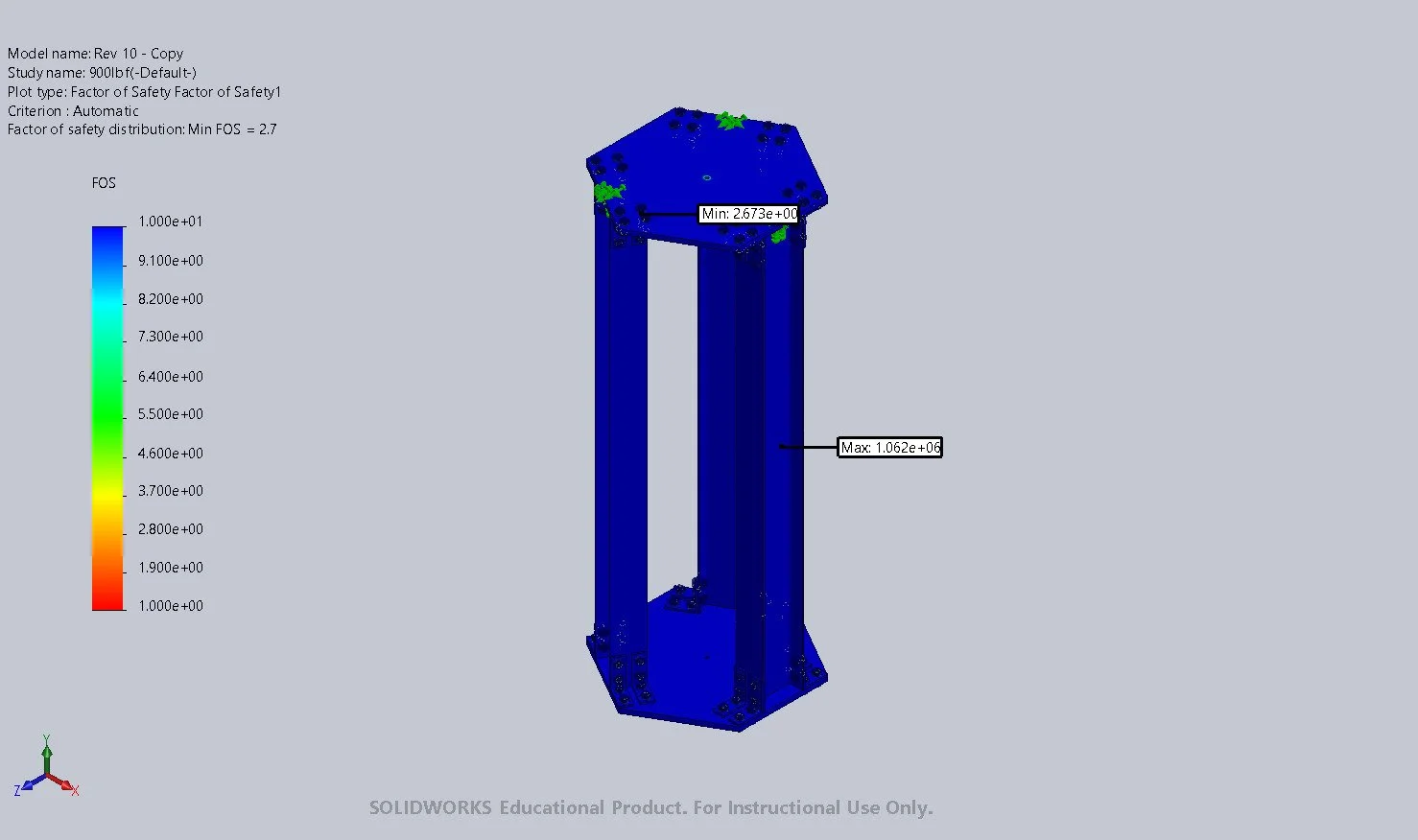

Designed all iterations of test stand and motor adapter using SOLIDWORKS

Verified structural integrity using classical hand methods and SOLIDWORKS FEA

Utilized machining methods to solve issues in assembly

Led and assisted in final assembly of test stand

Led and conducted two successful static fire tests of solid propellant rocket motors

Test stand specifications

Max applied load: 900 lbf

Max motor length: 40”

Max motor diameter: 12”

Motor interfaces with load cell via 1/2” bolt